AGV-SYSTEMS

DIMOS AGV systems are designed for maximum availability.

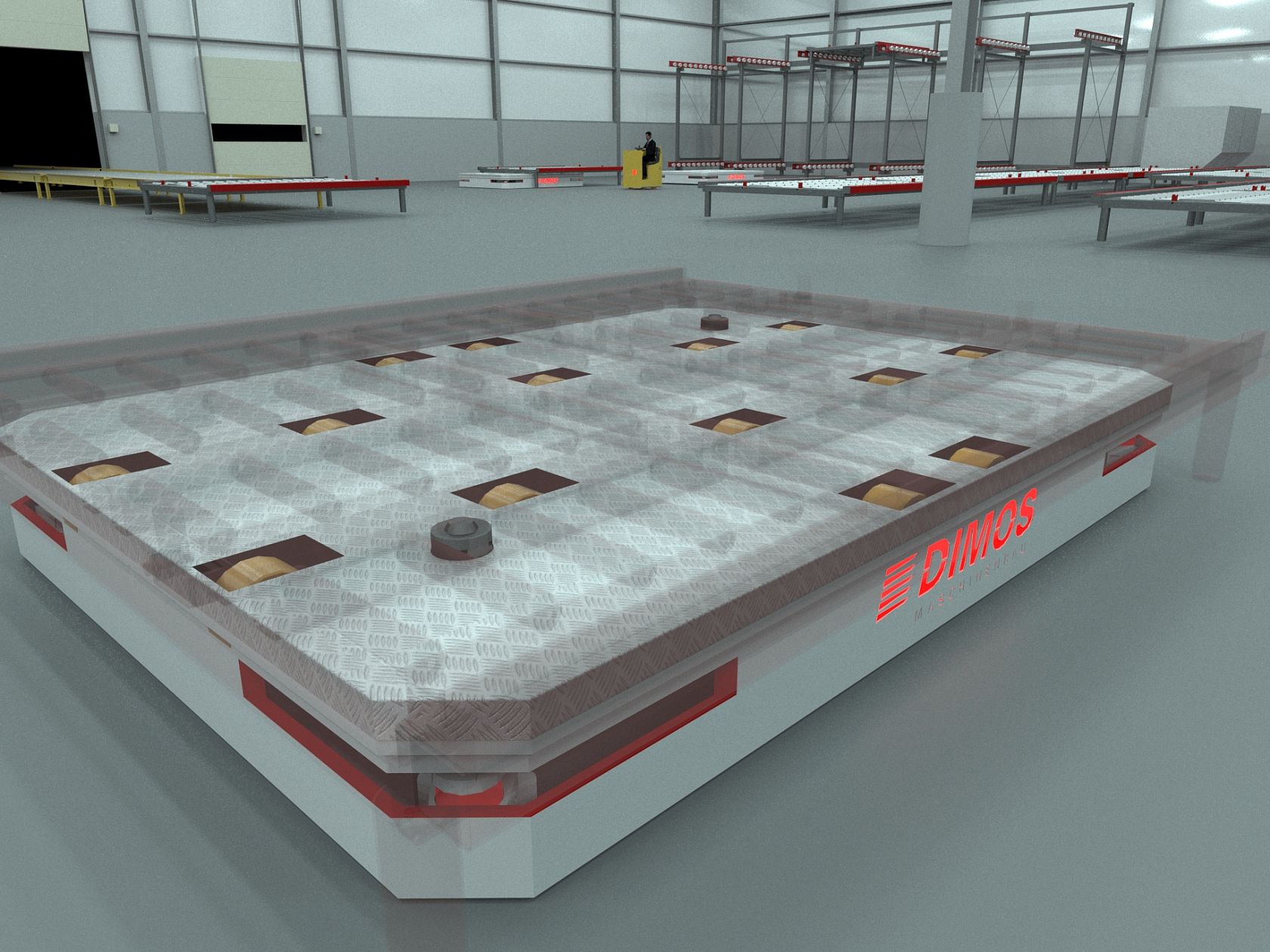

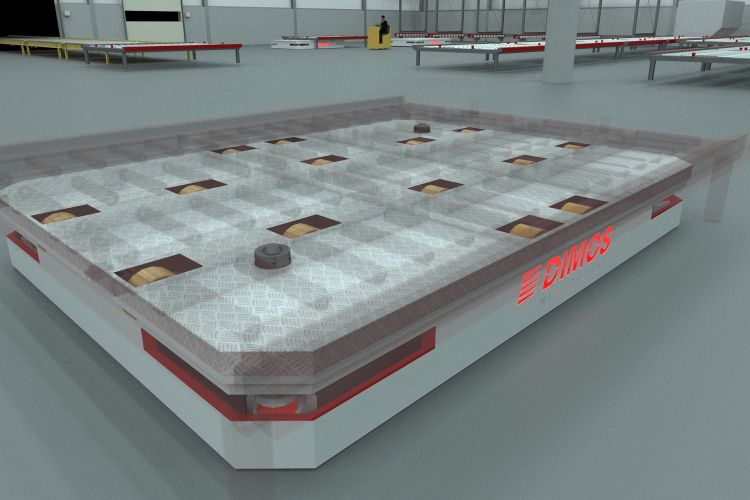

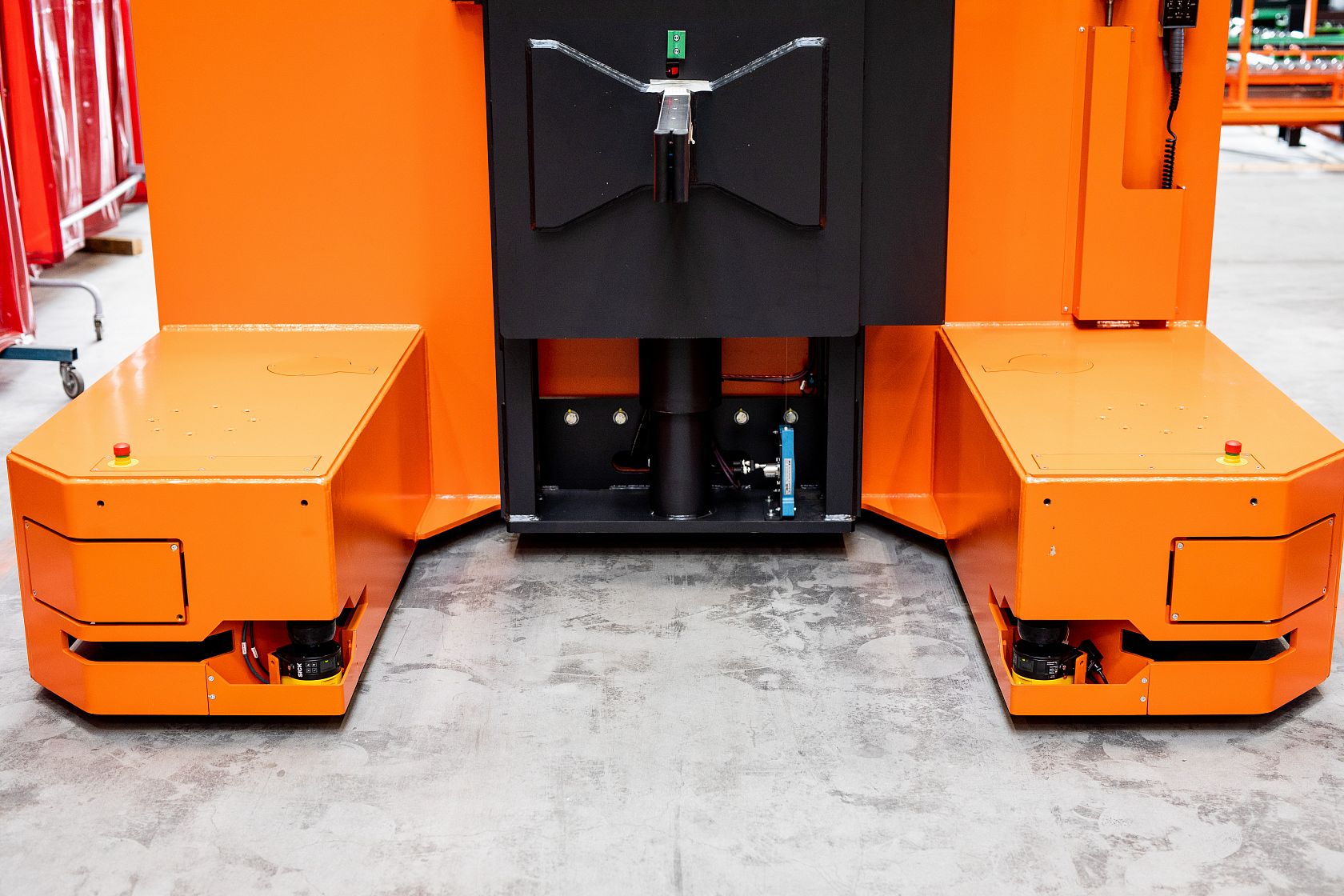

The basis of our automated guided vehicle systems are the most diverse logistics processes of our customers. Together we develop individually the most cost-efficient solution for you. With our fully autonomous vehicles, you can achieve both maximum availability and increased process efficiency. Positioning accuracy also plays an important role - only with this can excellent performance be guaranteed. And that also in high tonnages.

Challenge us!

Challenge us.

Together with you, we develop the right AGV / AGV system for your challenge!

THE Features

Depending on the configuration of the warehouse, we use different navigation systems or mixtures of navigation systems. In addition to the scanners of the personnel protection system, it is also important for the navigation to install local scanners in the warehouse so that a perfect coverage of the movement radii is guaranteed.

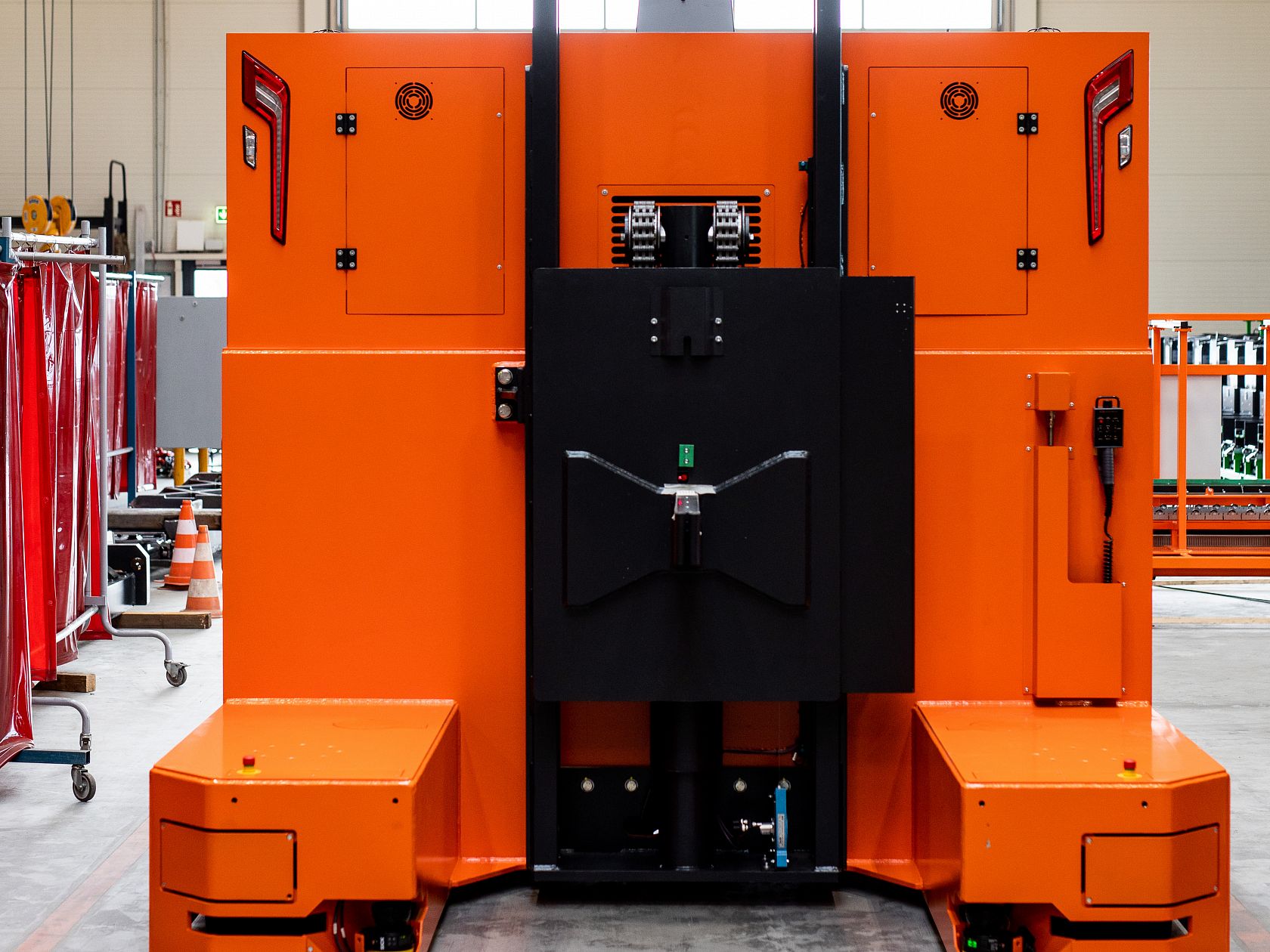

Our PPE (personal protection system) is mandatory to meet today's safety standards in the area of AGV/ AGV. This mobile type of area protection / access monitoring offers our customer maximum flexibility. Different protected areas can be created and defined. When an obstacle is detected, a protective measure is taken depending on the distance, such as speed reduction or automatic emergency braking.

We respond to your ideas - Currently, there are no automation solutions "off the shelf", which is why we project an individual system for each customer. Here we can respond precisely to your requirements and the warehouse situation and thus find the best solution for your handling task.

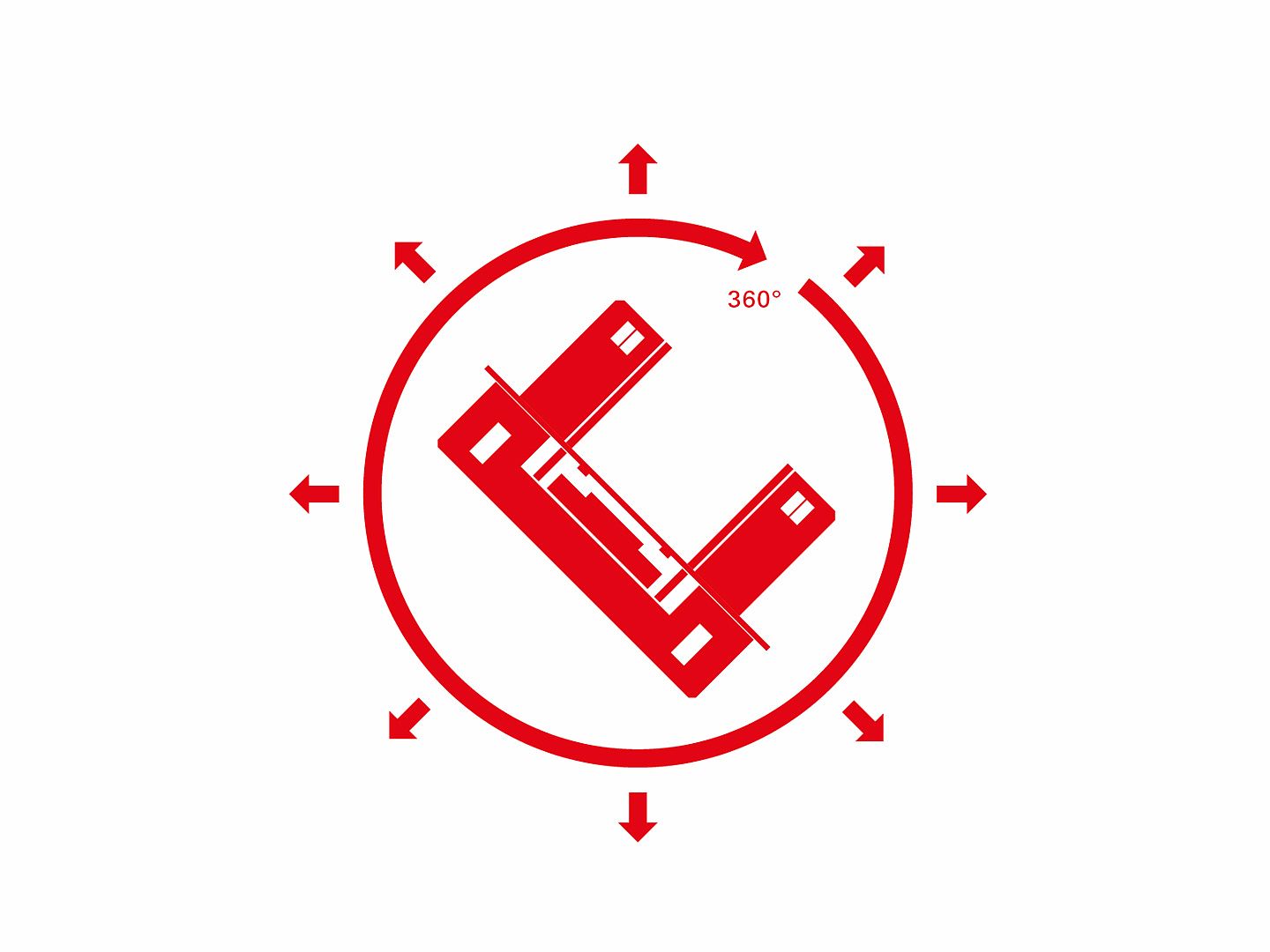

MAXIMUM MANEUVERABILITY & FLUID DRIVING MANEUVERS

- Enables maneuvering with millimeter precision

- Minimizes turning radius

- Smooth change from steering to transverse travel

- Increases travel efficiency and energy use

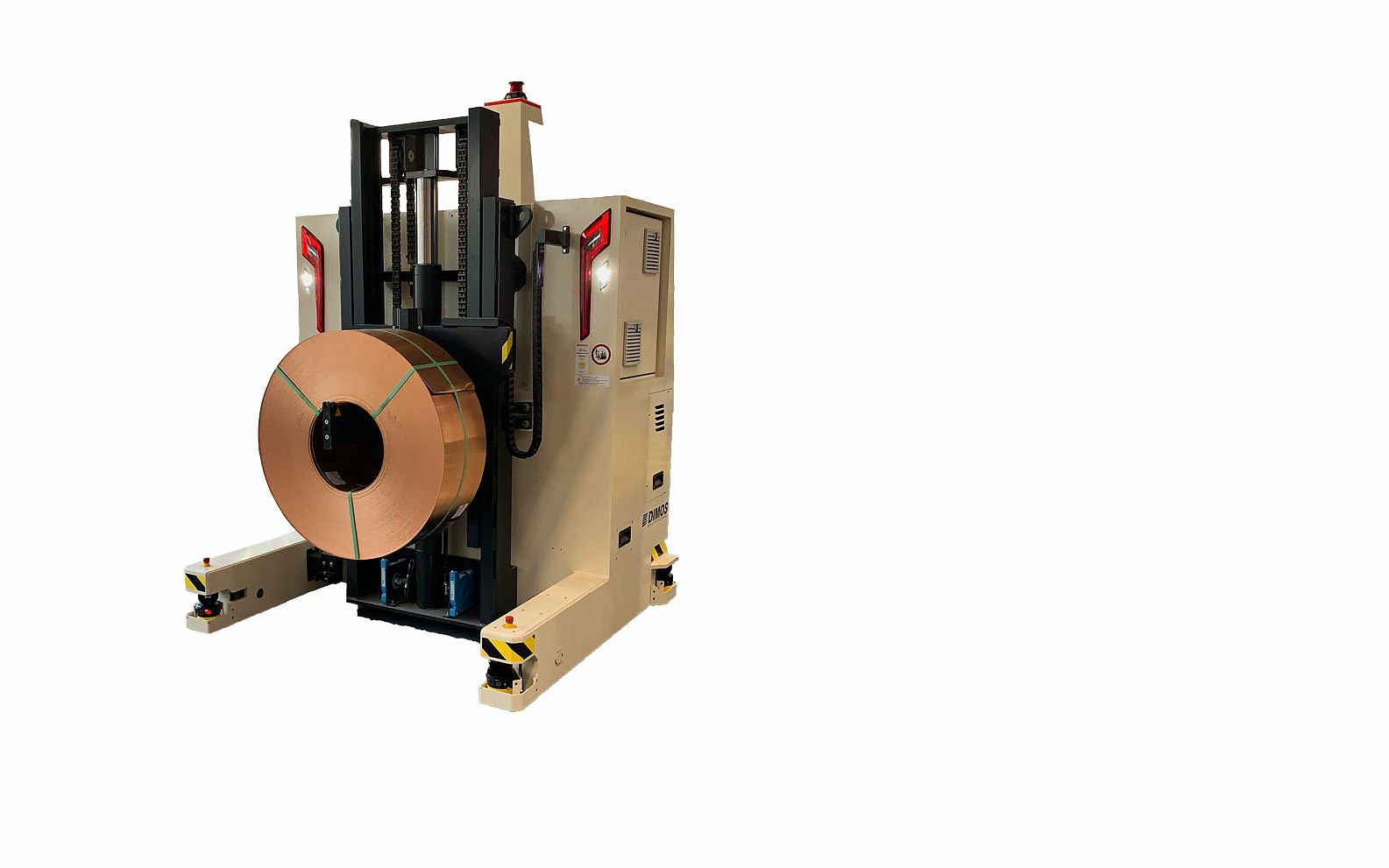

The lifting system for your automated vehicle is also configured to customer specifications. This means that we can also easily map lower clearance heights or higher load capacities. Like the rest of the vehicle, the lifting system is fully automatic and can lift and lower while the vehicle is moving or only when it is at a standstill, as desired. With the former option, we can significantly reduce process times.

By using different tires and drive strengths, our AGVs can be used both indoors and outdoors. Even driving uphill / downhill is no challenge for our driverless transport systems, whether loaded or unloaded.

THE AUTOMATED BATTERY CHANGING SYSTEM

Your AGV request?

We will be happy to advise you! Together we will find the right automated solution for your challenge.