AIR CARGO

VEHICLES

SYSTEM SOLUTIONS AT THE AIRPORT

The handling of goods and products at the air freight terminal is complex: goods have to be transported quickly and safely from A to B. The air freight terminal has to meet a wide range of requirements, be it in terms of weight, speed or temperature sensitivity. In the process, a wide variety of requirements must be met, be it in terms of weight, transport security, speed or temperature sensitivity. In order to be able to load aircraft optimally, baggage, freight or mail are bundled in unit load devices (ULDs). ULDs consist of pallets and containers and enable the easy transport of goods and products in large quantities. Numerous vehicles are used in the air cargo sector to handle, store and transport these ULDs. As a system supplier, DIMOS offers various solutions to optimize the process flow at the airport.

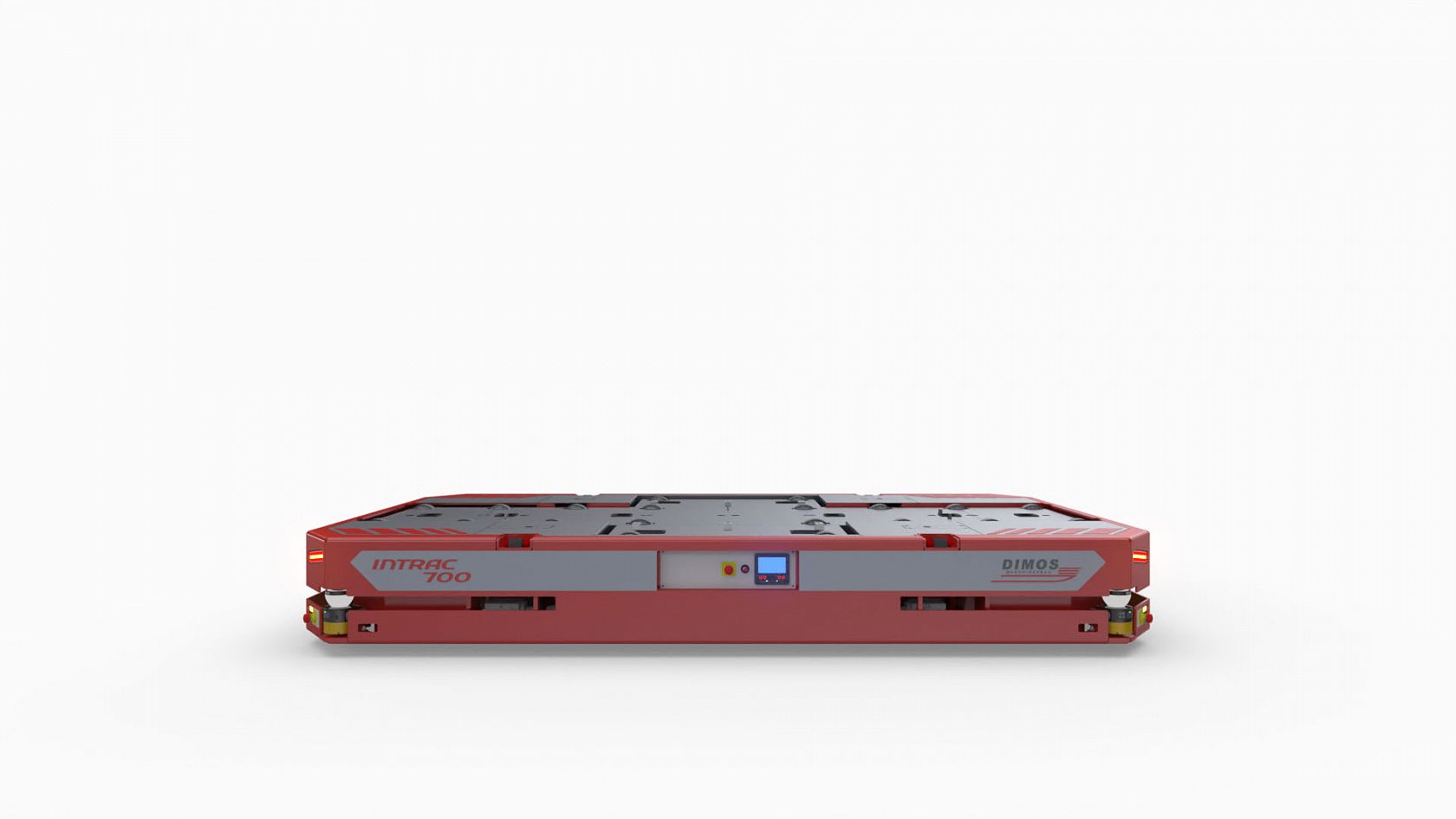

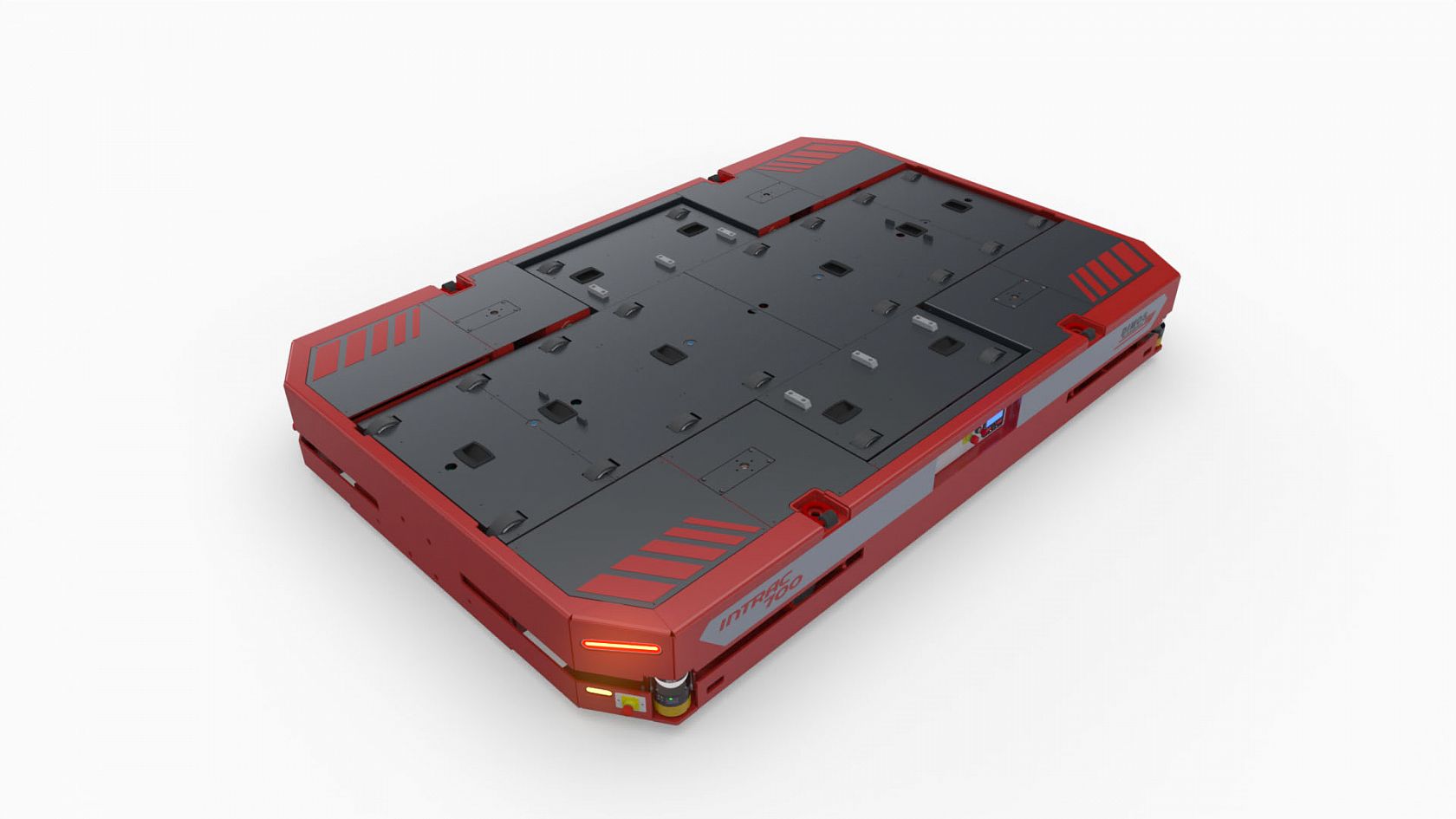

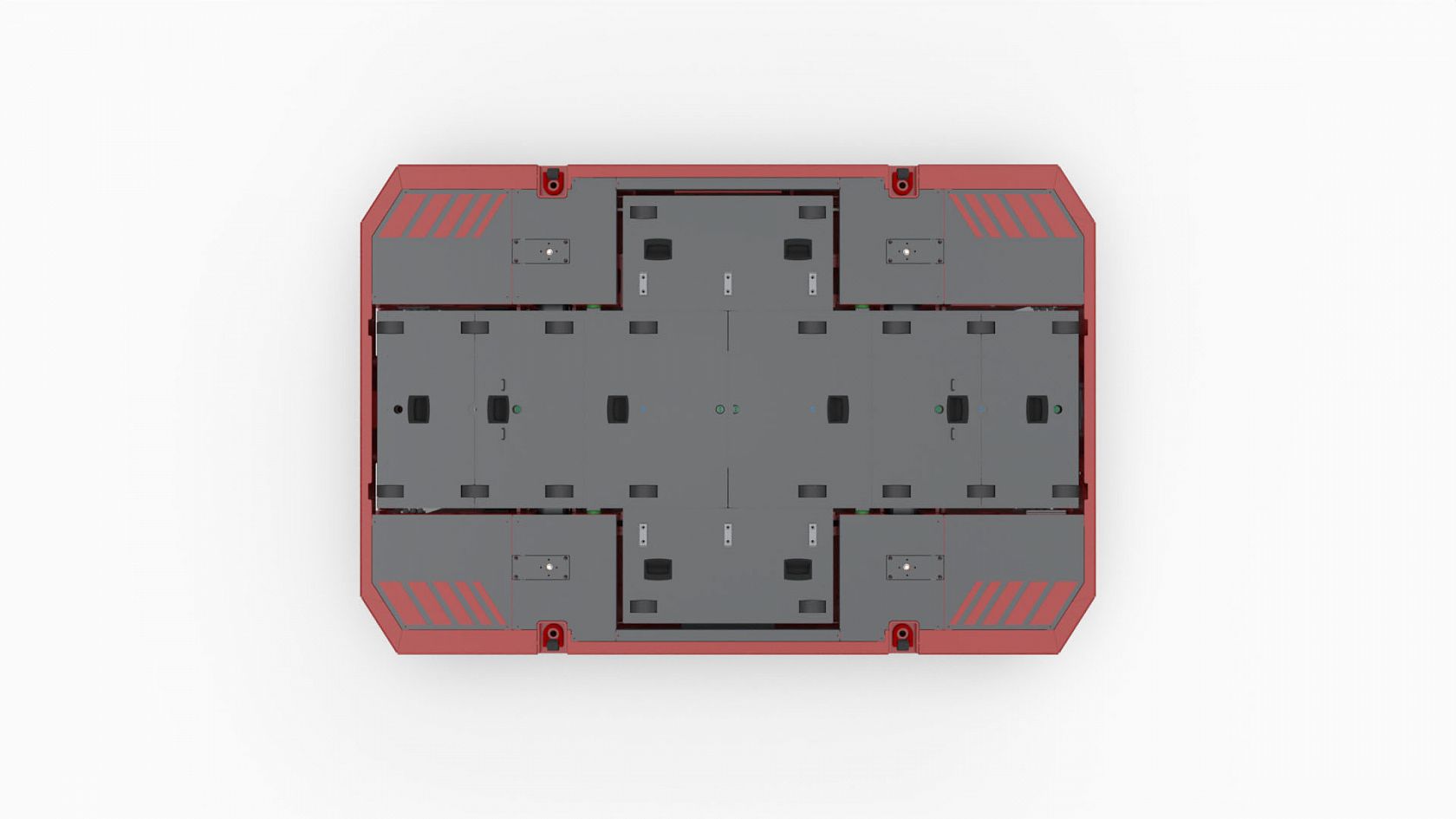

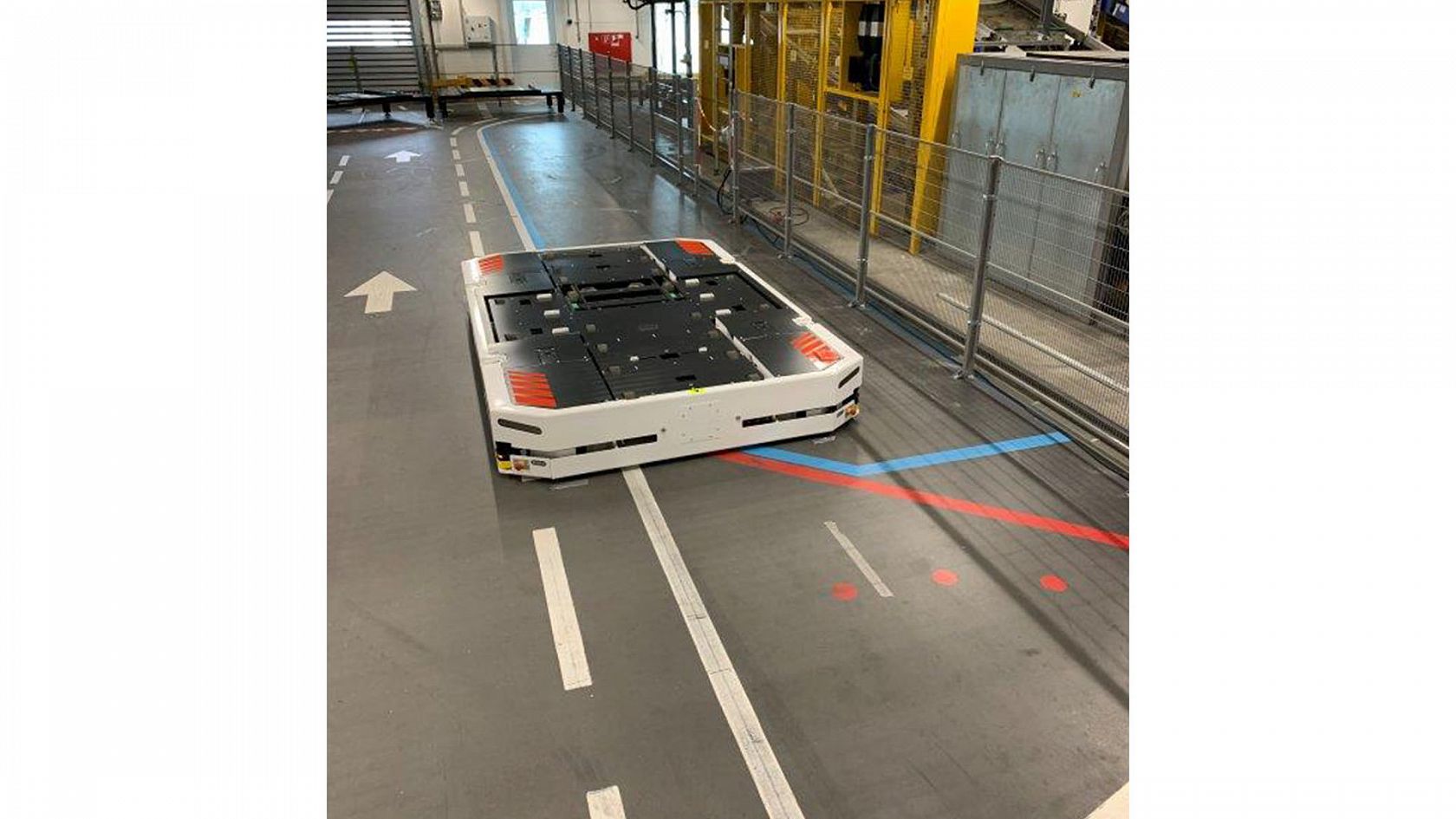

NEW: Intrac Pallet Mover

Do you have any questions?

We are happy to help you find the perfect vehicle for your application!

The X-Way Mover is offered in a total of 5 different series. Thus, it can be designed either for one standard ULD (10 feet) or for loading with 2 standard ULDs (20 feet). Other features, such as lifting height, energy package, etc., can also be freely selected. The X-Way Mover from DIMOS is already in use worldwide with all-electric operation. The automation of the product is also already thought of, so we can also offer a retrofitting of the already delivered vehicles.

ONE VEHICLE - THREE VARIANTS

Configured to suit your application, the DIMOS Pallet Mover is offered in three different versions. The standard model convinces with a comfortable cross-seat cabin, as well as the version with scissor lift table. If a towing variant is preferred, we have also developed a corresponding tiller device.

Even in its basic configuration, INTRAC arranges fully autonomous freight operation. But there is another way: In the basic concept of the Pallet Mover, the AGV unit can easily be temporarily replaced by a manual driver unit. "With INTRAC MOVE, we offer users the greatest possible flexibility to put together the optimum solution for their specific requirements . A mixed fleet of manually operated and fully automated vehicles is also possible," explains Pascal Schütz, responsible for sales and development at DIMOS. The decisive factor for the composition is the required capacity or the tonnage to be handled per year. If the requirements change, there is the option of upgrading or downgrading the existing vehicles. The system can be easily expanded. This enables users to plan capacity flexibly.

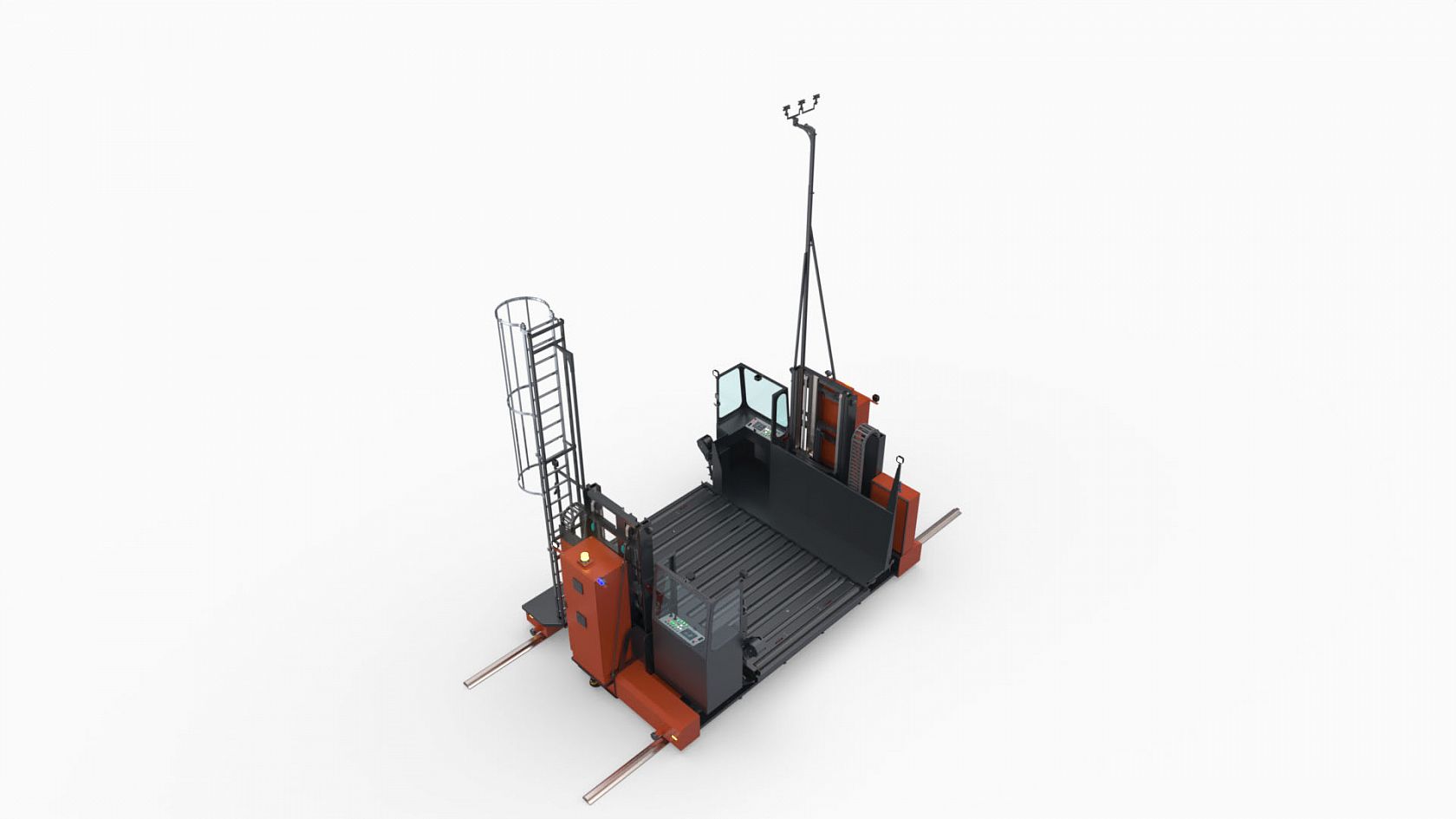

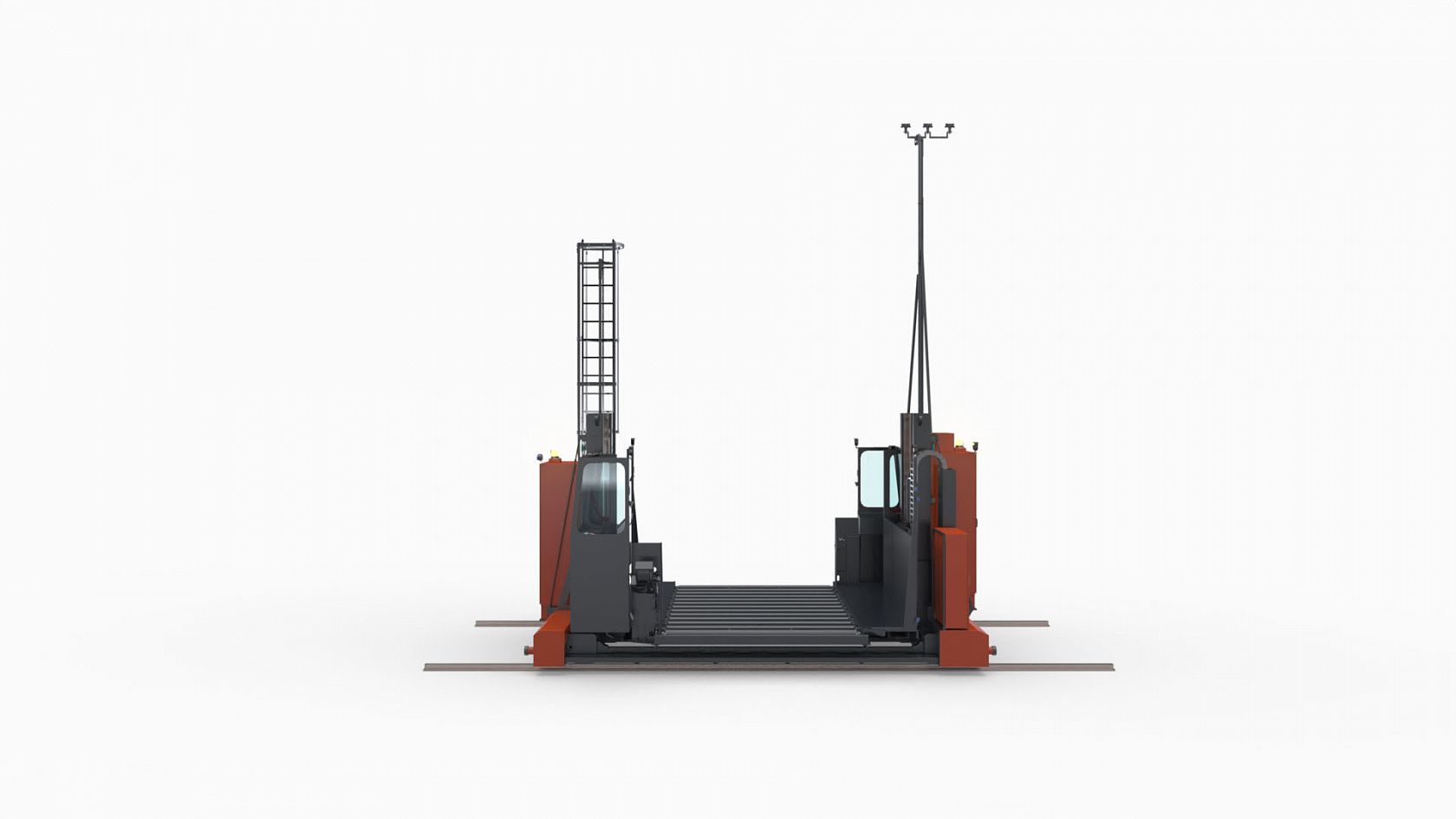

The roller deck tracks are either individually motorized or driven by the friction wheel mounted on the ETV. The ETV travels on 2 rails and is supplied with power via a conductor rail mounted on the floor or at the head end. The ergonomically designed operator's cab is equipped with an adjustable comfort seat. The controls & touch display are clearly arranged and user-friendly. The camera system provides the operator with an optimal view in both directions of travel and of the storage levels. Depending on the described expansion stages, the ETV can be operated manually, semi-automatically or fully automatically.

Your inquiry about Air Cargo Handling

We are happy to help you. As an internationally recognized supplier in the field of air cargo handling, we will find the right solution for your processes.